How Do You Manufacture Clothes

The Journey Behind Every Stitch

It’s much more than just a piece of fabric sewn together. It’s a reflection of your identity, creativity, culture, and values. Every hoodie, t-shirt, or dress is a reflection of the journey that begins before it’s in your closet.

Have you ever thought, “How do you manufacture clothes?“

At Plum Industry, we assist fashion companies, startups, and clothing manufacturers in developing transparent, durable, and reliable supply chains. This guide will walk you through every step of the process for clothing manufacturing from conception to the final delivery.

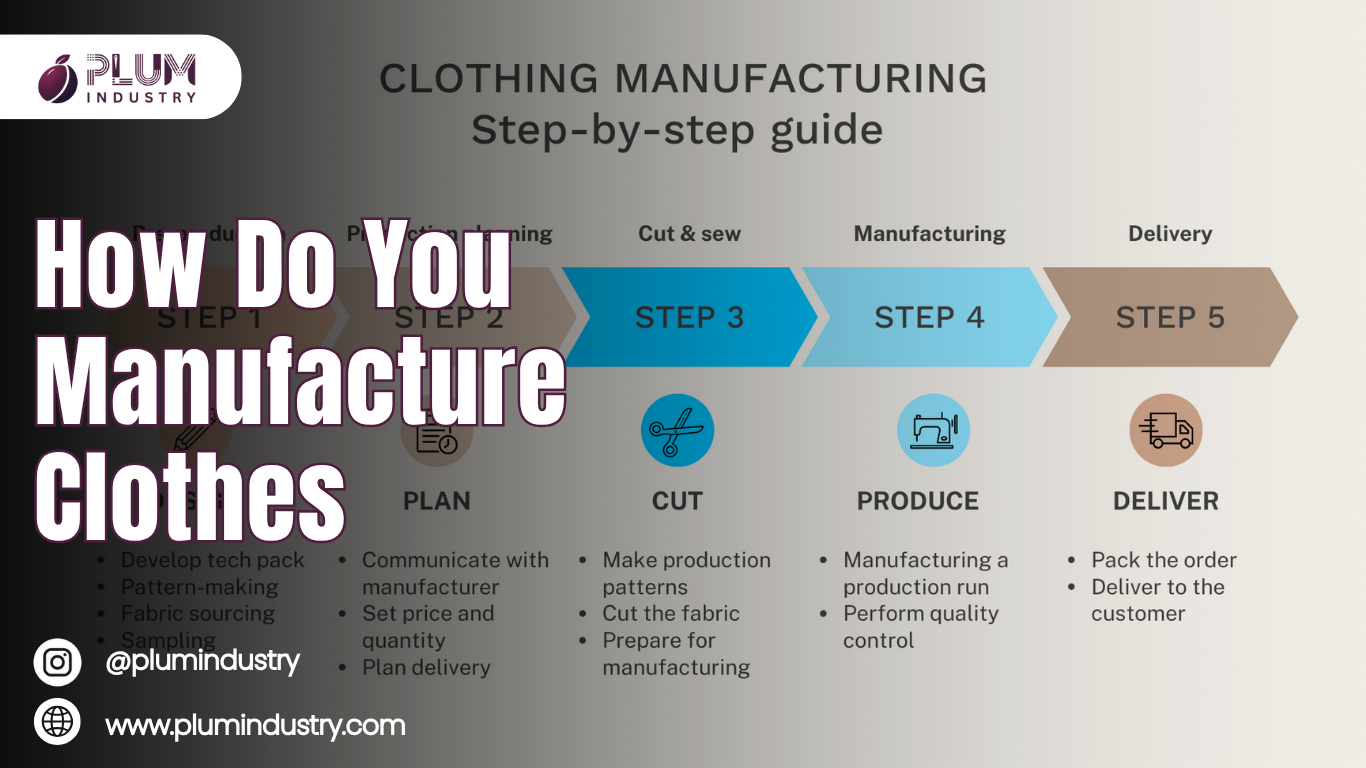

The Clothing Manufacturing Journey

The process of clothing manufacturing isn’t a one-step process; it’s a series of planned steps. Each step ensures that the final product meets high standards, matches market trends, and offers the best value for both businesses and consumers.

Step 1: Concept & Design

Every piece of clothing begins with an idea. Designers draw inspiration from trends in fashion as well as brand identities and consumer behavior to bring original concepts to life. This is where they define the direction, audience, and the feasibility of production for the collection.

Key Elements of the Design Stage

- Market research: finding new fashion trends, colors, seasonal palettes of color, and the preferences of customers.

- Sketching and CAD Design: Converting your innovative thoughts into precise patterns with Computer-Aided Design (CAD) tools to make it easy to modify and scale.

- Material Selection: Choosing trims, fabrics, and finishes that match the design aesthetic and also the comfort needs.

- Costing and Feasibility: Estimating materials, labor, and cost of production to guarantee profitability before moving forward.

In the Plum Industry, we have skilled design teams work together with customers to design items that are elegant, practical, and efficient, making sure that the design functions perfectly for clothing manufacturing on a large scale.

Step 2: The Raw Material Phase – Where It All Begins

After the design has been approved, the sourcing process begins. The sustainability, quality, and source of components determine the success of the final product and reputation for the brand.

Selecting the Right Fabric

There are three kinds of fabric:

- Natural fibers come from both animals and plants. They are soft, breathable, and comfy. Examples include wool, cotton, silk, linen, and hemp. Skin-sensitive people typically opt for natural fibers since they are healthy in the long run and are easy to break down.

- Synthetic fibers: Polyester, acrylic, and nylon are synthetic fibers derived from petroleum chemicals. They are tough, elastic, stretchy, and resist shrinking and wrinkling. Because they last for a long time and are affordable, they are commonly employed in sportswear and quick fashion.

- Blended fabrics, such as wool-acrylic blends and cotton-poly blends, combine the best characteristics of synthetic and natural fibers. For instance, cotton is soft, while polyester keeps things lasting longer.

Commonly Sourced Materials

- Sustainable Alternatives: Organic Cotton, the bamboo fiber, Tencel hemp, as well as recycled polyester.

- Accessories: Labels, zippers, snaps, buttons, laces, and trims.

- Dyes & Chemicals: Eco-certified dyes to ensure color consistency as well as safe handling.

Step 3: Pattern Making & Sampling

Before the clothing manufacturing process begins, the designers and pattern makers convert designs into a reality. This process ensures that the garments are comfortable, fit well, retain their structure, and appear as they were intended to when put on.

Key Steps:

- Pattern Development: Designing detailed plans of each component of a garment.

- Digital Grading: The process of scaling the base pattern into different dimensions while keeping proportions.

- Sample Production: Making prototypes to test drape, stitching accuracy, and ease of use.

- Tests of Fit and Revisions: Testing the fit of samples on mannequins or models, and then making adjustments based on feedback.

This step reduces the chance of errors and improves designs for mass production, thereby saving both time and money in production.

Step 4: Fabric Cutting

Once designs and samples have been finished, the fabric is moved to the cutting area. The accuracy of this step determines the efficiency of the material and overall quality of the garment.

Cutting Process:

- Fabric Spreading: Fabric layers are evenly spread across long tables for cutting.

- Marking patterns are strategically placed to limit the amount of waste.

- Cutting can be done by hand with electric shears or using cutting machines that are AI-driven to ensure precise cutting.

- Bundling: Pieces of cut fabric are grouped according to size as well as color, design, and style to make it easier for you to sew.

Plum Industry utilizes intelligent cutting and AI-based nesting methods, which reduce waste from fabric as well as speed up and improve cutting precision, thereby enhancing the efficiency of our costs and sustainability.

Step 5: Sewing & Assembly

Here is where true art meets technology. Expertly trained sewing operators and sophisticated machines are used to assemble fabric pieces into a finished garment.

Techniques & Operations

- Chain stitching

- Flat seaming and overlocking

- Hemming and blind stitching

- Buttonholes and button attachment

- Screen printing, embroidery, and digital printing (if needed)

Each workstation is focused on a specific task to ensure speed and consistency.

Step 6: Quality Control (QC)

Before they are shipped out, they go through a series of quality tests to ensure they meet the specifications of the brand in addition to international standards.

QC Parameters

- Stitching Precision: Examining thread strength, seam strength, and alignment.

- Measurements and Fit: Ensuring that all measurements are in line with the approved samples.

- Fabric & Color Accuracy: Detecting shrinkage, pilling, or dye irregularities.

- Label & Trim Positioning: The purpose of this is to verify the consistency of branding.

- Defect Management: Re-working or recycling damaged items to ensure the sustainability of the product.

Step 7: Finishing & Packaging

After quality approval is complete, the garments then move towards the finish line.

Final Touches Include

- Steaming or ironing: To reduce wrinkles and to improve appearance.

- Trimming loose threads: Ensuring the appearance of a polished, clean look.

- Add Brand Labels and Tags: Including dimensions, wash care, and logo information.

- Packaging: Folding, bagging, and storing clothes according to brand standards.

Plum Industry’s packaging is environmentally friendly and can be customized, which ensures that your branding is uniform from the factory to.

Step 8: Distribution & Logistics

The final stage will ensure that your product reaches global markets quickly and on time.

Logistics Process

- Garments are kept in controlled areas.

- Freight Coordination: Transporting goods via air, sea, or railway, based on budget and timelines.

- Customs & Documentation: Controlling the export documentation and ensuring compliance.

- Delivery to customers or retailers Delivery to customers or retailers using trusted partners.

Sustainability in Clothing Manufacturing

Sustainability will not just be a luxury; it’s vital. The apparel industry is moving to adopt eco-friendly and ethical clothing manufacturing methods.

Modern Sustainable Practices

- Recycled and organic fabrics

- Assuring fair pay and safe working conditions

- Promotion of recycling models and the circular model

- Transitioning to carbon-neutral supply chains

Plum Industry integrates sustainability at every stage, from raw materials to global logistics. We can help you build a sustainable brand.

Why Partner with Plum Industry

When businesses ask, “How do you manufacture clothes efficiently and ethically?” The answer is easy using the right partner. At Plum Industry, we help businesses and support companies:

- Get materials from reliable, ethical suppliers.

- Control factories to ensure consistency in quality and openness.

- Improve logistics to facilitate global trade.

- Integrate sustainability into every phase of production.

Whatever your company’s size, we can help you bridge that gap between you and your supply chain in the world.

Conclusion

How do you manufacture clothes? It’s a complex process that requires imagination as well as precision and commitment to every step, from designing and material selection to making, sewing, finalizing, and distribution worldwide.

Today, clothing manufacturing is more than just creating clothes and accessories; it’s about combining the art of craftsmanship with sustainability, as well as innovation and ethical production. Plum Industry, we assist fashion labels of all sizes in transforming their ideas into quality collections with transparent, efficient, and ethical manufacturing practices.

Are you ready to bring your concepts into existence? Contact with the Plum Industry and begin your clothing manufacturing from concept to international success, safely and sustainably.

FAQs

How do you make clothing step-by-step?

It entails creating, sourcing materials and patterns, cutting, sewing, finishing, quality control, and distribution.

What does it take to start clothing manufacturing?

The length of time varies from one or two weeks for the simplest objects to a long time for collections with a lot of complexity.

Can small businesses start their own clothing manufacturing line?

Absolutely. With the right partners, even small fashion brands can launch successful clothing lines. Plum Industry offers scalable production and sourcing solutions tailored for startups and emerging labels.

What’s the most sustainable method to produce clothing?

Utilizing eco-friendly materials, fair labor practices, recycling, and carbon-neutral shipping.

Why Should You Partner with Plum Industry for Clothing Manufacturing?

We offer complete solutions from source to delivery, ensuring the highest level of efficiency, ethical conduct, and profit.

What are the benefits of outsourcing clothing manufacturing?

Outsourcing helps brands save time, reduce costs, and access specialized expertise. Partnering with a trusted manufacturer like Plum Industry ensures consistent quality, ethical production, and global delivery efficiency.